Carbon and fiber composite tubes are the basis of many modern high-tech applications – from robotics and measurement technology to aviation. Precise cut-outs, drill holes and contours are required to integrate these components functionally.

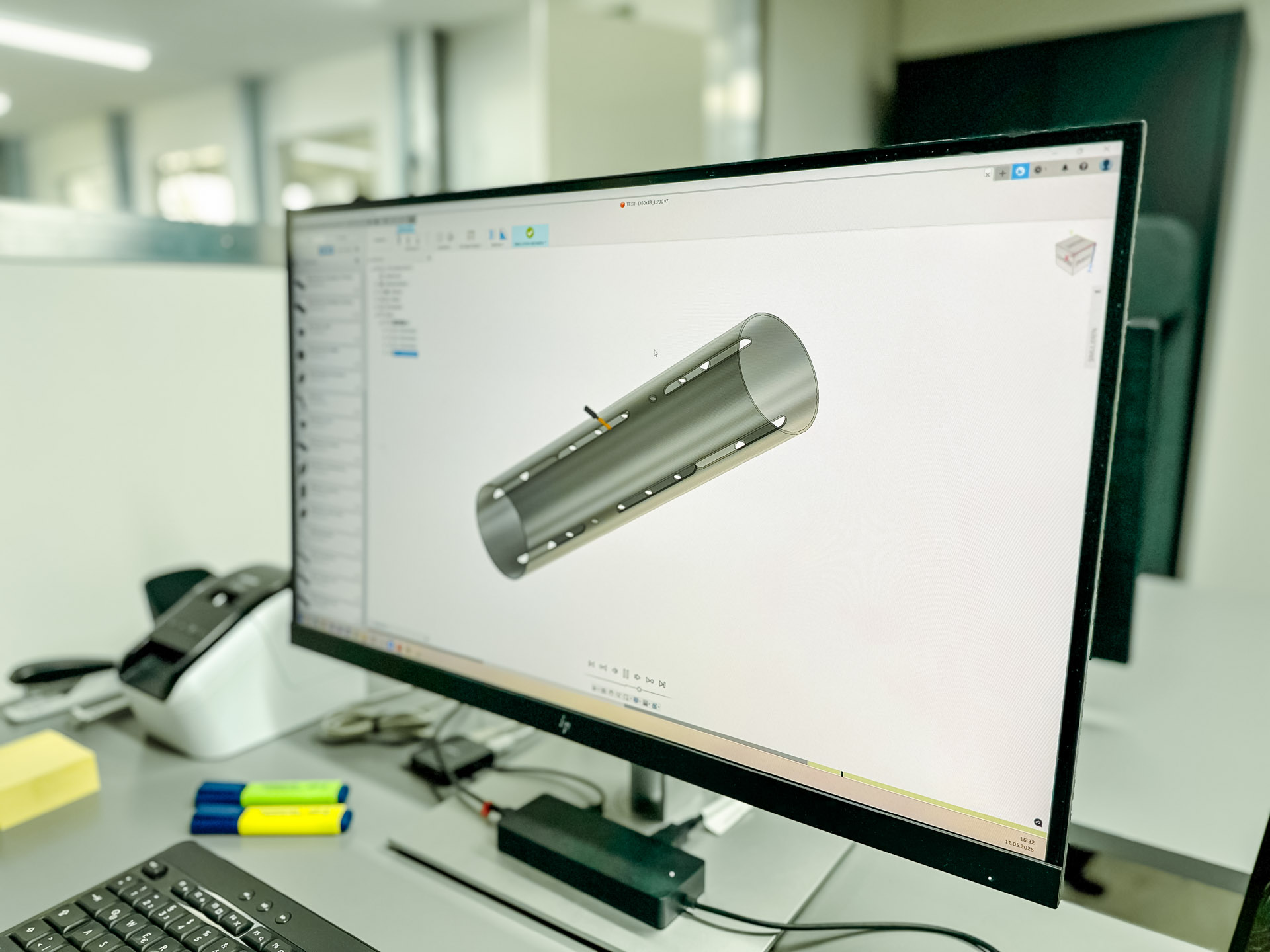

We offer you a highly specialized solution for precisely this: 360° CNC tube machining along the entire circumference of the tube – efficient, precise and fibre-compatible.

With our rotary CNC technology, we process tubes over the entire surface along the unwindingwithout reclamping, without loss of position – and with the highest standards of dimensional accuracy and repeatability.

The machining of round tubes poses particular challenges in practice: conventional milling techniques quickly reach their limits with rotationally symmetrical components – especially when uniform tolerances, complete all-round machining or complex cut-outs are required. This is precisely where we come in with our specialized 360° CNC machining technology.

Our CNC system is designed to machine the entire circumference of the tube along the so-called unwinding process. This means that the tube is continuously rotated during the machining process so that every area of the casing can be reached and milled with absolute precision – without any reclamping. This means that even geometrically demanding elements such as circularly distributed holes, segmented recesses, fits for connecting elements or longitudinal and transverse slots can be implemented cleanly and efficiently.

This technology offers considerable advantages, especially for thin-walled or multi-layer CFRP tubes. The low-stress workpiece fixture reduces deformation and prevents the introduction of unwanted stresses into the fiber structure. This is essential in order to maintain the mechanical integrity and performance of the components – especially in applications where high demands are placed on strength, weight and fatigue strength.

Another advantage: Rotary machining in a single clamping operation eliminates the need for manual reworking, positioning errors and time-consuming reclamping processes. This enables us to achieve consistently high repeat accuracy, which is crucial for both series components and high-precision one-offs and prototypes.

In addition, our technology enables optimum adaptation to your specific design specifications: Free-form contours, special cut-outs, combined machining zones – we implement all of this directly on the finished CFRP tube. We can even reliably process asymmetrical components with variable wall thicknesses or combined material layers – always tailored to the requirements of your application.

Whether you need a simple functional hole, a ready-to-install interface or a complex, multi-sided structure – we ensure that your idea is implemented with the utmost precision and efficiency.

We offer you complete 360° CNC milling of tubes made of carbon (CFRP), glass fiber (GFRP) and hybrid materials – precisely tailored to your requirements. The tube is machined along its entire circumference, which means that even complex geometries such as recesses, fits, windows or free-form contours can be implemented efficiently and precisely.

Our machines enable rotary processing of the entire tube body along the unwinding process, without reclamping or changing position – this increases dimensional accuracy, reduces tolerance errors and saves valuable processing time. Even with thin-walled or multi-layer tubes that are sensitive to mechanical stress, we achieve optimum results thanks to low-stress fixtures.

Machining is always carried out in a material-specific and fiber-oriented manner so that the structural integrity of the tubes is maintained. From simple slotted holes and precise milling for sensors to complex geometries with multiple machining zones – we implement your CAD specifications precisely and with repeat accuracy.

Combinations with other components, e.g. milled connection surfaces or precisely fitting panel components, can also be easily realized – ideal for integrated assembly solutions in which tubular and panel elements work together perfectly.

Key technical data:

Machinable outer diameter: up to 250 mm

Maximum tube length: up to 2,000 mm

Materials: CFRP, GFRP, hybrid tubes and other composite materials

Prototypes, small series and series production possible

Whether as individual parts, functional carriers or system components – our CNC machining ensures that your tubular components are produced exactly as you need them: dimensionally accurate, ready for assembly and economically produced.

With our specialized 360° milling technology, we offer you not just a machining solution – but a real competitive advantage. The combination of state-of-the-art CNC technology, fiber-compatible workpiece clamping and years of experience in working with fiber composite materials opens up numerous technical, economic and logistical advantages for you.

Every tubular component is produced exactly according to your technical drawing or CAD data – from simple openings to complex free-form contours. This gives you solutions that are perfectly tailored to your design and can be seamlessly integrated into existing systems.

The rotary processing guarantees an even load on the workpiece and prevents fiber damage or delamination. Even with thin-walled or multi-layer CFRP tubes, the structure remains intact – a decisive advantage for safety-critical applications.

As the tube does not have to be reclamped during the entire machining process, there is no need for time-consuming intermediate processes, manual reworking or additional fixtures. This saves time, minimizes sources of error and reduces the overall costs of your component production.

Our production processes are designed for efficiency and reproducibility – ideal for small series, medium quantities and short-term prototype projects. Even complex contours can be realized in a short time and with consistently high quality.

Thanks to precise machining and exact dimensional accuracy, the milled tube components can be further processed directly – whether by gluing, screwing or press-fitting. This makes assembly easier and increases the accuracy of fit in your overall assembly.

Whether a single part, assembly or series project – we implement your requirements with the utmost care. Benefit from our experience in working with sophisticated fiber composites and our high-performance CNC technology.