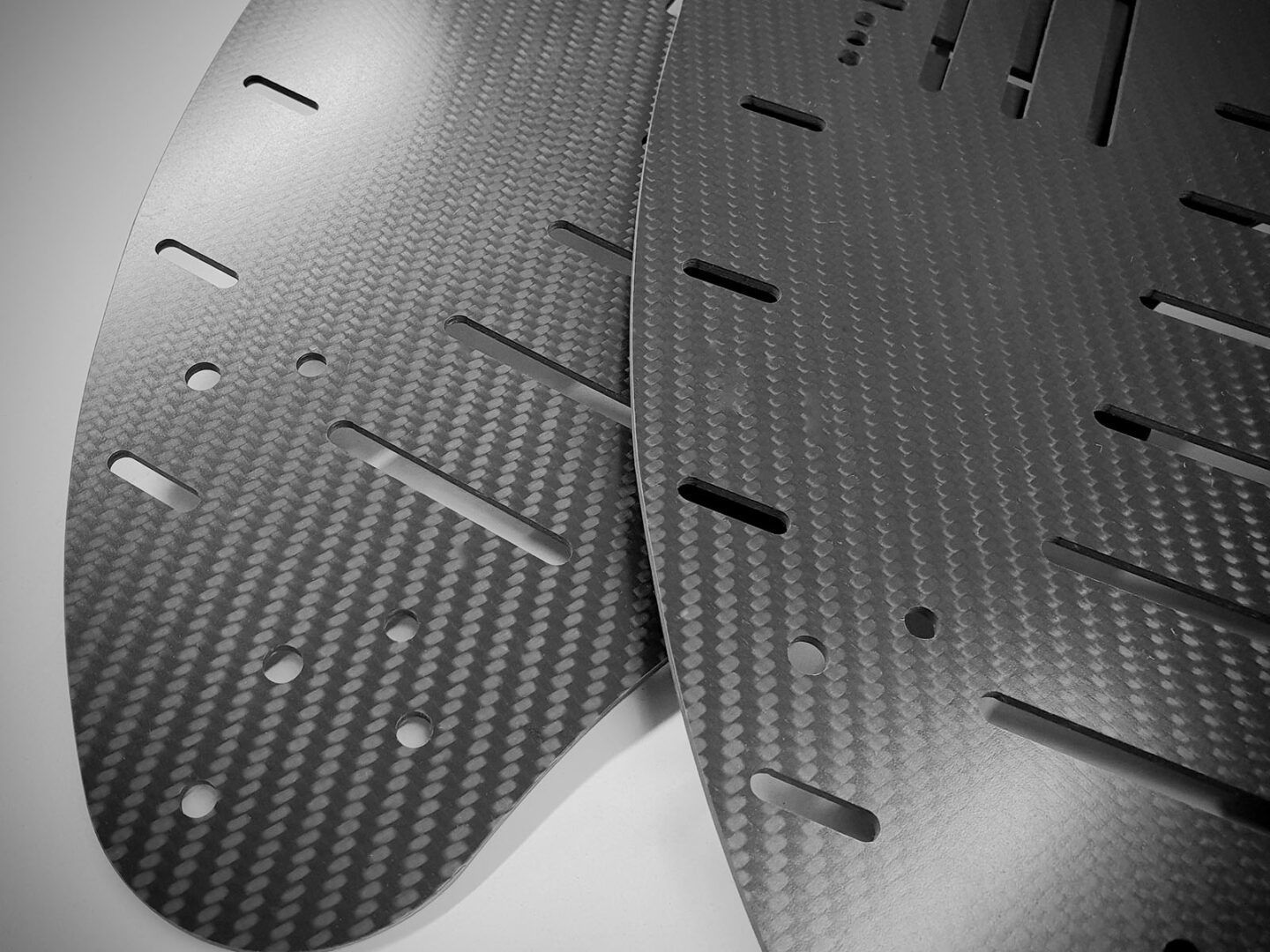

The processing of fiber composites such as carbon (CFRP) and glass fiber (GFRP) requires special expertise, experience and state-of-the-art technology.

We use CNC milling technology with diamond-coated tools to produce components with maximum precision, clean cutting edges and the best surface qualities.

Whether you need individual parts, prototypes or series parts – we offer you a reliable and custom-fit solution for your application.

Our specialty is the machining of 2.5D milled parts exactly according to your CAD data or technical drawings.

More than just standard – we process your fiber composite components according to your individual specifications and precisely to measure.

Our CNC milling machines enable the economical and precise processing of carbon sheets, profiles, tubes and sandwich structures. Thanks to state-of-the-art CAM programming and specialized tools, we mill your components efficiently and gently.

We manufacture for you:

Contours, openings, pockets and chamfers

Holes, countersinks and threads (milled, drilled or with threaded inserts)

Double-sided and reverse-sided processing of panels and profiles

Engraving of logos, serial numbers and part numbers

Particular care is required for carbon components: processing is carried out with low dust levels, gentle on the workpiece and in compliance with tight tolerances. Our experts will be happy to advise you on the optimum production strategy – tailored to your requirements.

Our milling services are aimed specifically at customers who work with fiber composite materials such as carbon fiber (CFRP), glass fiber (GFRP) or other thermoset laminates. We have access to a wide range of semi-finished products – from standard panels to customized sandwich structures.

Typical materials in our portfolio:

Carbon sheets made from prepregs, pressed with UD layers (e.g. 0°/90°) and fabric cover layers

Surfaces: semi-gloss or high-gloss

Temperature resistance up to 120 °C, higher on request

Special bodies and special materials on request

It is also possible to combine different layer structures or inserts. Our team will be happy to support you in selecting the optimum material for your application – whether for lightweight construction, mechanical engineering, robotics or measurement technology.

We get the maximum out of the material and machine

Our production capabilities cover a broad spectrum – from small, high-precision components to large-scale parts.

Important key data for implementing your design:

Maximum component size: 2,200 x 900 mm

Material thicknesses: 0.2 mm to 30 mm

Inner radii: from R0.5 mm

Tolerances:

Standard: according to DIN ISO 2768

Optional: +/- 0.05 mm for critical geometries

Panel thicknesses: +/- 0.2 mm, +/- 0.05 mm if required (by surface grinding)

This manufacturing accuracy is ideal for applications where maximum precision is required – such as components for optical devices, robotics, motor sports or aviation.

Your time is valuable – we deliver quickly and flexibly

Whether you need a prototype or a series: Our aim is to deliver your milled parts quickly and reliably. We keep common semi-finished products in stock at all times and can therefore guarantee short lead times.

Our typical delivery times:

Sample parts: Shipment within 48 hours

Small batches and series: Delivery within 10-15 working days

Express production possible by arrangement

You will receive a free and non-binding offer within 24 hours – individually tailored to your requirements.

Are you planning a project with CFRP or GFRP components? Then you’ve come to the right place. Whether you need a component with complex geometry or a simple plate with defined holes – we will turn your idea into reality.

Free quote within 24 hours!